- Landline

- (800) 666-0766

- Fax

- (800) 691-0031

- sales@aspcinc.com

- 2147918325531389

- Website

- www.aspcinc.com

- Order

- www.aspcinc.com

Description

We remain the best qualified quality and customer-focused global provider of today’s industry leading sewer cleaning accessories and parts along with a one-of-a-kind line of finished products. Our product offering is unmatched in the industry. We are your source for hard to find Sewer Truck and Pump parts, a wide range of sewer cleaning assemblies and parts including Leader Hose, Sewer Cleaning Nozzles, Lateral and Mainline Root Cutters, Aluminum and Steel Sewer Cleaning "Tuff" Tubes® known for their seamless design and durability, Hose Mending Equipment and associated highly ranked accessories. We welcome you to browse our online catalog at our website.

Keywords aspc, american sewer parts & cleaning, tuff tube, hose, sewer cleaning.

Reviews

Opening hours

24/7/365 - Request an online quote at anytime, at https://www.aspcinc.com. Closed during all major US holidays.

Payment Options

American Express , Visa , Check , Discover , MasterCard

Products And Services

-

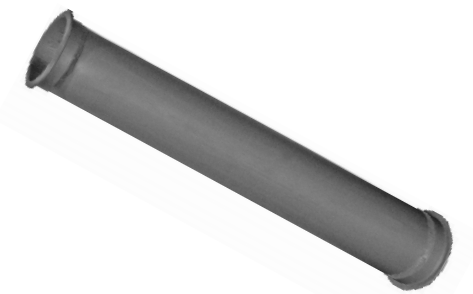

Male Bandlock Catch Basin Tube (dig tube) (S8500-00454)

Tuff Tube® has been designed specifically for industries such as the industrial vacuum and sewer cleaningindustry. The Tuff Tube vacuum tube is used to vacuum sand, pieces of pipe, grit, rocks, water, concrete, dirtand organics. This mixture is very abrasive to the interior of the vacuum tube, to say the least, not to mentionthe bumping and banging the tube receives on the steel manhole frame when entering a manhole. In both the wear and dent resistance tests, the Tuff Tube performed significantly better than both the.072” and the .090” thick 3004-H22 irrigation tube. Tuff Tube showed a 346% increase in wear resistancecompared to the .072” thick sample, and a 272% increase compared to the .090” thick sample. Naturally,the tests conducted here do not entirely capture what can and does happen in the field. It is however, fairlysafe to state from the data above, that the Tuff Tube® would last about twice as long as a .072” or .090” thickirrigation product when used in a highly abrasive environment. Tuff Tube seamless tubing has a wall thickness of.100”, which is .010” thicker than any other 6” 8”aluminum tube in the industrial sewer and vacuummarket. Tuff Tube is also heat-treated. Thus, over-time,it becomes work-hardended, which in-turn prolongsits career in the field. It has a material hardness of C15 to C16 on a Rockwellscale compared to 3004.H22 irrigation tube, whichtested at C10 to C12. which improved this product’swear rate by 41% over conventional aluminumvacuum tubing and a tensile strength of 35 KSI, whichmakes the Tuff Tube 28% more dent resistant overconventional vacuum tubing available and providesbetter ovality. In keeping the integrity of the tubing round, theTuff Tube® helps ensure better air flow which equalsbetter C. F. M. and total vacuum efficiency. A dent in avacuum tube restricts air flow creating less C.F.M. andless vacuum efficiency. For more product options, please see our Parts List Sheet.

Link: Male Bandlock Catch Basin Tube (dig tube) (S8500-00454)

-

Female Bandlock Catch Basin Tube (dig tube) (S8510-00287C)

Tuff Tube® has been designed specifically for industries such as the industrial vacuum and sewer cleaningindustry. The Tuff Tube vacuum tube is used to vacuum sand, pieces of pipe, grit, rocks, water, concrete, dirtand organics. This mixture is very abrasive to the interior of the vacuum tube, to say the least, not to mentionthe bumping and banging the tube receives on the steel manhole frame when entering a manhole. In both the wear and dent resistance tests, the Tuff Tube performed significantly better than both the.072” and the .090” thick 3004-H22 irrigation tube. Tuff Tube showed a 346% increase in wear resistancecompared to the .072” thick sample, and a 272% increase compared to the .090” thick sample. Naturally,the tests conducted here do not entirely capture what can and does happen in the field. It is however, fairlysafe to state from the data above, that the Tuff Tube® would last about twice as long as a .072” or .090” thickirrigation product when used in a highly abrasive environment. Tuff Tube seamless tubing has a wall thickness of.100”, which is .010” thicker than any other 6” 8”aluminum tube in the industrial sewer and vacuummarket. Tuff Tube is also heat-treated. Thus, over-time,it becomes work-hardended, which in-turn prolongsits career in the field. It has a material hardness of C15 to C16 on a Rockwellscale compared to 3004.H22 irrigation tube, whichtested at C10 to C12. which improved this product’swear rate by 41% over conventional aluminumvacuum tubing and a tensile strength of 35 KSI, whichmakes the Tuff Tube 28% more dent resistant overconventional vacuum tubing available and providesbetter ovality. In keeping the integrity of the tubing round, theTuff Tube® helps ensure better air flow which equalsbetter C. F. M. and total vacuum efficiency. A dent in avacuum tube restricts air flow creating less C.F.M. andless vacuum efficiency. For more product options, please see our Parts List Sheet.

Link: Female Bandlock Catch Basin Tube (dig tube) (S8510-00287C)

-

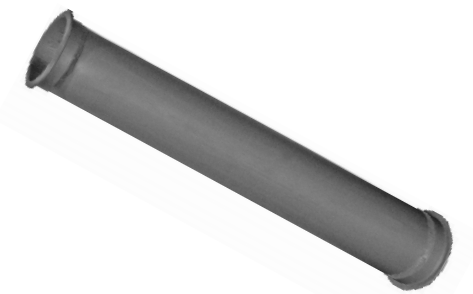

Bandlock Intake Tube (S8510-00285)

Tuff Tube® has been designed specifically for industries such as the industrial vacuum and sewer cleaningindustry. The Tuff Tube vacuum tube is used to vacuum sand, pieces of pipe, grit, rocks, water, concrete, dirtand organics. This mixture is very abrasive to the interior of the vacuum tube, to say the least, not to mentionthe bumping and banging the tube receives on the steel manhole frame when entering a manhole. In both the wear and dent resistance tests, the Tuff Tube performed significantly better than both the.072” and the .090” thick 3004-H22 irrigation tube. Tuff Tube showed a 346% increase in wear resistancecompared to the .072” thick sample, and a 272% increase compared to the .090” thick sample. Naturally,the tests conducted here do not entirely capture what can and does happen in the field. It is however, fairlysafe to state from the data above, that the Tuff Tube® would last about twice as long as a .072” or .090” thickirrigation product when used in a highly abrasive environment. Tuff Tube seamless tubing has a wall thickness of.100”, which is .010” thicker than any other 6” 8”aluminum tube in the industrial sewer and vacuummarket. Tuff Tube is also heat-treated. Thus, over-time,it becomes work-hardended, which in-turn prolongsits career in the field. It has a material hardness of C15 to C16 on a Rockwellscale compared to 3004.H22 irrigation tube, whichtested at C10 to C12. which improved this product’swear rate by 41% over conventional aluminumvacuum tubing and a tensile strength of 35 KSI, whichmakes the Tuff Tube 28% more dent resistant overconventional vacuum tubing available and providesbetter ovality. In keeping the integrity of the tubing round, theTuff Tube® helps ensure better air flow which equalsbetter C. F. M. and total vacuum efficiency. A dent in avacuum tube restricts air flow creating less C.F.M. andless vacuum efficiency. For more product options, please see our Parts List Sheet.

-

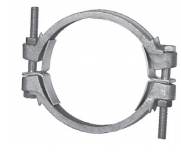

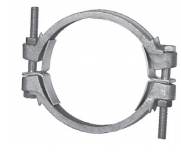

Bandlock / Ringlock Style Clamp (U42587)

Aluminum versions for clamping aluminum tube flanges. Steel versions for clamping steel to steel tube flanges. For more product options, please see our Parts List Sheet.

-

Aquatech® Style Tubes w/ Riveted Steel Couplers - Intake Tube (AT150461A)

Tuff Tube® has been designed specifically for industries such as the industrial vacuum and sewer cleaningindustry. The Tuff Tube vacuum tube is used to vacuum sand, pieces of pipe, grit, rocks, water, concrete, dirtand organics. This mixture is very abrasive to the interior of the vacuum tube, to say the least, not to mentionthe bumping and banging the tube receives on the steel manhole frame when entering a manhole. In both the wear and dent resistance tests, the Tuff Tube performed significantly better than both the.072” and the .090” thick 3004-H22 irrigation tube. Tuff Tube showed a 346% increase in wear resistancecompared to the .072” thick sample, and a 272% increase compared to the .090” thick sample. Naturally,the tests conducted here do not entirely capture what can and does happen in the field. It is however, fairlysafe to state from the data above, that the Tuff Tube® would last about twice as long as a .072” or .090” thickirrigation product when used in a highly abrasive environment. Tuff Tube seamless tubing has a wall thickness of.100”, which is .010” thicker than any other 6” 8”aluminum tube in the industrial sewer and vacuummarket. Tuff Tube is also heat-treated. Thus, over-time,it becomes work-hardended, which in-turn prolongsits career in the field. It has a material hardness of C15 to C16 on a Rockwellscale compared to 3004.H22 irrigation tube, whichtested at C10 to C12. which improved this product’swear rate by 41% over conventional aluminumvacuum tubing and a tensile strength of 35 KSI, whichmakes the Tuff Tube 28% more dent resistant overconventional vacuum tubing available and providesbetter ovality. In keeping the integrity of the tubing round, theTuff Tube® helps ensure better air flow which equalsbetter C. F. M. and total vacuum efficiency. A dent in avacuum tube restricts air flow creating less C.F.M. andless vacuum efficiency. For more product options, please see our Parts List Sheet.

Link: Aquatech® Style Tubes w/ Riveted Steel Couplers - Intake Tube (AT150461A)

-

Aquatech® Style Tubes w/ Riveted Steel Couplers - Catch Basin Tubes (dig tube) (AT150161)

Tuff Tube® has been designed specifically for industries such as the industrial vacuum and sewer cleaningindustry. The Tuff Tube vacuum tube is used to vacuum sand, pieces of pipe, grit, rocks, water, concrete, dirtand organics. This mixture is very abrasive to the interior of the vacuum tube, to say the least, not to mentionthe bumping and banging the tube receives on the steel manhole frame when entering a manhole. In both the wear and dent resistance tests, the Tuff Tube performed significantly better than both the.072” and the .090” thick 3004-H22 irrigation tube. Tuff Tube showed a 346% increase in wear resistancecompared to the .072” thick sample, and a 272% increase compared to the .090” thick sample. Naturally,the tests conducted here do not entirely capture what can and does happen in the field. It is however, fairlysafe to state from the data above, that the Tuff Tube® would last about twice as long as a .072” or .090” thickirrigation product when used in a highly abrasive environment. Tuff Tube seamless tubing has a wall thickness of.100”, which is .010” thicker than any other 6” 8”aluminum tube in the industrial sewer and vacuummarket. Tuff Tube is also heat-treated. Thus, over-time,it becomes work-hardended, which in-turn prolongsits career in the field. It has a material hardness of C15 to C16 on a Rockwellscale compared to 3004.H22 irrigation tube, whichtested at C10 to C12. which improved this product’swear rate by 41% over conventional aluminumvacuum tubing and a tensile strength of 35 KSI, whichmakes the Tuff Tube 28% more dent resistant overconventional vacuum tubing available and providesbetter ovality. In keeping the integrity of the tubing round, theTuff Tube® helps ensure better air flow which equalsbetter C. F. M. and total vacuum efficiency. A dent in avacuum tube restricts air flow creating less C.F.M. andless vacuum efficiency. For more product options, please see our Parts List Sheet.

Link: Aquatech® Style Tubes w/ Riveted Steel Couplers - Catch Basin Tubes (dig tube) (AT150161)

-

Vactor® and Vac-Con® Style Tubes - Intake Tubes w/ Welded Flanges (UA34763L)

Tuff Tube® has been designed specifically for industries such as the industrial vacuum and sewer cleaningindustry. The Tuff Tube vacuum tube is used to vacuum sand, pieces of pipe, grit, rocks, water, concrete, dirtand organics. This mixture is very abrasive to the interior of the vacuum tube, to say the least, not to mentionthe bumping and banging the tube receives on the steel manhole frame when entering a manhole. In both the wear and dent resistance tests, the Tuff Tube® performed significantly better than both the.072” and the .090” thick 3004-H22 irrigation tube. Tuff Tube® showed a 346% increase in wear resistancecompared to the .072” thick sample, and a 272% increase compared to the .090” thick sample. Naturally,the tests conducted here do not entirely capture what can and does happen in the field. It is however, fairlysafe to state from the data above, that the Tuff Tube® would last about twice as long as a .072” or .090” thickirrigation product when used in a highly abrasive environment. Tuff Tube® seamless tubing has a wall thickness of.100”, which is .010” thicker than any other 6” 8”aluminum tube in the industrial sewer and vacuummarket. Tuff Tube® is also heat-treated. Thus, over-time,it becomes work-hardended, which in-turn prolongsits career in the field. It has a material hardness of C15 to C16 on a Rockwellscale compared to 3004.H22 irrigation tube, whichtested at C10 to C12. which improved this product’swear rate by 41% over conventional aluminumvacuum tubing and a tensile strength of 35 KSI, whichmakes the Tuff Tube® 28% more dent resistant overconventional vacuum tubing available and providesbetter ovality. In keeping the integrity of the tubing round, theTuff Tube® helps ensure better air flow which equalsbetter C. F. M. and total vacuum efficiency. A dent in avacuum tube restricts air flow creating less C.F.M. andless vacuum efficiency. For more product options, please see our Parts List Sheet.

Link: Vactor® and Vac-Con® Style Tubes - Intake Tubes w/ Welded Flanges (UA34763L)

-

Vactor® Style Flat Flange Quick Clamp w/ Trimline Handle (U16584)

Trimline 6” and 8” Quick Clamps The Trimline Quick Clamps used to secure Vactor® and Vac-Con® flange style tubes, have been designed with a trimline handle in both ‘U’ and ‘V’ style clamps. This feature enables the handle to hug the body of the clamp when it is drawn over center to tighten the clamp over the vacuum tube flanges. The design greatly decreases the chances of the handle getting caught on clothing, equipment and or even manhole lids or stairs versus a standard style clamp handle, which sticks out from the clamp’s outer profile. The result is a safer and more efficient clamp for use in the field. For more product options, please see our Parts List Sheet.

Link: Vactor® Style Flat Flange Quick Clamp w/ Trimline Handle (U16584)

-

Vac-Con® Style Flat Flange Quick Clamp w/ Trimline Handle (VC690-0073)

Trimline 6” and 8” Quick Clamps The Trimline Quick Clamps used to secure Vactor and Vac-Con flange style tubes, have been designed with a trimline handle in both ‘U’ and ‘V’ style clamps.This feature enables the handle to hug the body of the clamp when it isdrawn over center to tighten the clamp over the vacuum tube flanges. The design greatly decreases the chances of the handle getting caught onclothing, equipment and or even manhole lids or stairs versus a standardstyle clamp handle, which sticks out from the clamp’s outer profile. The result is a safer and more effi cient clamp for use in the field. For more product options, please see our Parts List Sheet.

Link: Vac-Con® Style Flat Flange Quick Clamp w/ Trimline Handle (VC690-0073)

-

Vactor® and Vac-Con® Style Tubes - Catch Basin w/ Welded Ends (dig tube) (UA34766)

Tuff Tube® has been designed specifically for industries such as the industrial vacuum and sewer cleaning industry. The Tuff Tube® vacuum tube is used to vacuum sand, pieces of pipe, grit, rocks, water, concrete, dirtand organics. This mixture is very abrasive to the interior of the vacuum tube, to say the least, not to mentionthe bumping and banging the tube receives on the steel manhole frame when entering a manhole. In both the wear and dent resistance tests, the Tuff Tube® performed significantly better than both the.072” and the .090” thick 3004-H22 irrigation tube. Tuff Tube showed a 346% increase in wear resistancecompared to the .072” thick sample, and a 272% increase compared to the .090” thick sample. Naturally,the tests conducted here do not entirely capture what can and does happen in the field. It is however, fairlysafe to state from the data above, that the Tuff Tube® would last about twice as long as a .072” or .090” thickirrigation product when used in a highly abrasive environment. Tuff Tube® seamless tubing has a wall thickness of.100”, which is .010” thicker than any other 6” 8”aluminum tube in the industrial sewer and vacuummarket. Tuff Tube® is also heat-treated. Thus, over-time,it becomes work-hardended, which in-turn prolongsits career in the field. It has a material hardness of C15 to C16 on a Rockwellscale compared to 3004.H22 irrigation tube, whichtested at C10 to C12. which improved this product’swear rate by 41% over conventional aluminumvacuum tubing and a tensile strength of 35 KSI, whichmakes the Tuff Tube® 28% more dent resistant overconventional vacuum tubing available and providesbetter ovality. In keeping the integrity of the tubing round, theTuff Tube® helps ensure better air flow which equalsbetter C. F. M. and total vacuum efficiency. A dent in avacuum tube restricts air flow creating less C.F.M. andless vacuum efficiency. For more product options, please see our Parts List Sheet.

Link: Vactor® and Vac-Con® Style Tubes - Catch Basin w/ Welded Ends (dig tube) (UA34766)

-

Vactor® and Vac-Con® Style Tubes - Intake Tubes w/ Riveted Steel Flanges (U34763H)

Tuff Tube® has been designed specifically for industries such as the industrial vacuum and sewer cleaningindustry. The Tuff Tube vacuum tube is used to vacuum sand, pieces of pipe, grit, rocks, water, concrete, dirtand organics. This mixture is very abrasive to the interior of the vacuum tube, to say the least, not to mentionthe bumping and banging the tube receives on the steel manhole frame when entering a manhole. In both the wear and dent resistance tests, the Tuff Tube® performed significantly better than both the.072” and the .090” thick 3004-H22 irrigation tube. Tuff Tube® showed a 346% increase in wear resistancecompared to the .072” thick sample, and a 272% increase compared to the .090” thick sample. Naturally,the tests conducted here do not entirely capture what can and does happen in the field. It is however, fairlysafe to state from the data above, that the Tuff Tube® would last about twice as long as a .072” or .090” thickirrigation product when used in a highly abrasive environment. Tuff Tube® seamless tubing has a wall thickness of.100”, which is .010” thicker than any other 6” 8”aluminum tube in the industrial sewer and vacuummarket. Tuff Tube® is also heat-treated. Thus, over-time,it becomes work-hardended, which in-turn prolongsits career in the field. It has a material hardness of C15 to C16 on a Rockwellscale compared to 3004.H22 irrigation tube, whichtested at C10 to C12. which improved this product’swear rate by 41% over conventional aluminumvacuum tubing and a tensile strength of 35 KSI, whichmakes the Tuff Tube® 28% more dent resistant overconventional vacuum tubing available and providesbetter ovality. In keeping the integrity of the tubing round, theTuff Tube® helps ensure better air flow which equalsbetter C. F. M. and total vacuum efficiency. A dent in avacuum tube restricts air flow creating less C.F.M. andless vacuum efficiency. For more product options, please see our Parts List Sheet.

Link: Vactor® and Vac-Con® Style Tubes - Intake Tubes w/ Riveted Steel Flanges (U34763H)

-

Pipe Flange w/ Drilled Rivet Holes (U15338C)

For more product options, please see our Parts List Sheet.

-

Vactor® and Vac-Con® Style Catch Basin Tube w/ Riveted Steel Ends (dig tube) (U34766-1)

Tuff Tube® has been designed specifically for industries such as the industrial vacuum and sewer cleaningindustry. The Tuff Tube® vacuum tube is used to vacuum sand, pieces of pipe, grit, rocks, water, concrete, dirtand organics. This mixture is very abrasive to the interior of the vacuum tube, to say the least, not to mentionthe bumping and banging the tube receives on the steel manhole frame when entering a manhole. In both the wear and dent resistance tests, the Tuff Tube® performed significantly better than both the.072” and the .090” thick 3004-H22 irrigation tube. Tuff Tube showed a 346% increase in wear resistancecompared to the .072” thick sample, and a 272% increase compared to the .090” thick sample. Naturally,the tests conducted here do not entirely capture what can and does happen in the field. It is however, fairlysafe to state from the data above, that the Tuff Tube® would last about twice as long as a .072” or .090” thickirrigation product when used in a highly abrasive environment. Tuff Tube® seamless tubing has a wall thickness of.100”, which is .010” thicker than any other 6” 8”aluminum tube in the industrial sewer and vacuummarket. Tuff Tube® is also heat-treated. Thus, over-time,it becomes work-hardended, which in-turn prolongsits career in the field. It has a material hardness of C15 to C16 on a Rockwellscale compared to 3004.H22 irrigation tube, whichtested at C10 to C12. which improved this product’swear rate by 41% over conventional aluminumvacuum tubing and a tensile strength of 35 KSI, whichmakes the Tuff Tube 28% more dent resistant overconventional vacuum tubing available and providesbetter ovality. In keeping the integrity of the tubing round, theTuff Tube® helps ensure better air flow which equalsbetter C. F. M. and total vacuum efficiency. A dent in avacuum tube restricts air flow creating less C.F.M. andless vacuum efficiency. For more product options, please see our Parts List Sheet.

Link: Vactor® and Vac-Con® Style Catch Basin Tube w/ Riveted Steel Ends (dig tube) (U34766-1)

-

Vactor® Style Hydro-Excavation Tubes (UA34763KHE)

Tuff Tube® has been designed specifically for industries such as the industrial vacuum and sewer cleaningindustry. The Tuff Tube® vacuum tube is used to vacuum sand, pieces of pipe, grit, rocks, water, concrete, dirtand organics. This mixture is very abrasive to the interior of the vacuum tube, to say the least, not to mentionthe bumping and banging the tube receives on the steel manhole frame when entering a manhole. In both the wear and dent resistance tests, the Tuff Tube® performed significantly better than both the.072” and the .090” thick 3004-H22 irrigation tube. Tuff Tube® showed a 346% increase in wear resistancecompared to the .072” thick sample, and a 272% increase compared to the .090” thick sample. Naturally,the tests conducted here do not entirely capture what can and does happen in the field. It is however, fairlysafe to state from the data above, that the Tuff Tube® would last about twice as long as a .072” or .090” thickirrigation product when used in a highly abrasive environment. Tuff Tube® seamless tubing has a wall thickness of.100”, which is .010” thicker than any other 6” 8”aluminum tube in the industrial sewer and vacuummarket. Tuff Tube® is also heat-treated. Thus, over-time,it becomes work-hardended, which in-turn prolongsits career in the field. It has a material hardness of C15 to C16 on a Rockwellscale compared to 3004.H22 irrigation tube, whichtested at C10 to C12. which improved this product’swear rate by 41% over conventional aluminumvacuum tubing and a tensile strength of 35 KSI, whichmakes the Tuff Tube® 28% more dent resistant overconventional vacuum tubing available and providesbetter ovality. For more product options, please see our Parts List Sheet.

-

8" Riveted Female Aquatech® Style Hydro (AT238007HE)

Tuff Tube® has been designed specifically for industries such as the industrial vacuum and sewer cleaningindustry. The Tuff Tube vacuum tube is used to vacuum sand, pieces of pipe, grit, rocks, water, concrete, dirtand organics. This mixture is very abrasive to the interior of the vacuum tube, to say the least, not to mentionthe bumping and banging the tube receives on the steel manhole frame when entering a manhole. In both the wear and dent resistance tests, the Tuff Tube® performed significantly better than both the.072” and the .090” thick 3004-H22 irrigation tube. Tuff Tube® showed a 346% increase in wear resistancecompared to the .072” thick sample, and a 272% increase compared to the .090” thick sample. Naturally,the tests conducted here do not entirely capture what can and does happen in the field. It is however, fairlysafe to state from the data above, that the Tuff Tube® would last about twice as long as a .072” or .090” thickirrigation product when used in a highly abrasive environment. Tuff Tube® seamless tubing has a wall thickness of.100”, which is .010” thicker than any other 6” 8”aluminum tube in the industrial sewer and vacuummarket. Tuff Tube® is also heat-treated. Thus, over-time,it becomes work-hardended, which in-turn prolongsits career in the field. It has a material hardness of C15 to C16 on a Rockwellscale compared to 3004.H22 irrigation tube, whichtested at C10 to C12. which improved this product’swear rate by 41% over conventional aluminumvacuum tubing and a tensile strength of 35 KSI, whichmakes the Tuff Tube® 28% more dent resistant overconventional vacuum tubing available and providesbetter ovality. For more product options, please see our Parts List Sheet.

-

Welded Male Bandlock ® Style / Hydro Cuff End (S8500-00455AHE)

Tuff Tube® has been designed specifically for industries such as the industrial vacuum and sewer cleaningindustry. The Tuff Tube vacuum tube is used to vacuum sand, pieces of pipe, grit, rocks, water, concrete, dirtand organics. This mixture is very abrasive to the interior of the vacuum tube, to say the least, not to mentionthe bumping and banging the tube receives on the steel manhole frame when entering a manhole. In both the wear and dent resistance tests, the Tuff Tube performed significantly better than both the.072” and the .090” thick 3004-H22 irrigation tube. Tuff Tube showed a 346% increase in wear resistancecompared to the .072” thick sample, and a 272% increase compared to the .090” thick sample. Naturally,the tests conducted here do not entirely capture what can and does happen in the field. It is however, fairlysafe to state from the data above, that the Tuff Tube® would last about twice as long as a .072” or .090” thickirrigation product when used in a highly abrasive environment. Tuff Tube seamless tubing has a wall thickness of.100”, which is .010” thicker than any other 6” 8”aluminum tube in the industrial sewer and vacuummarket. Tuff Tube is also heat-treated. Thus, over-time,it becomes work-hardended, which in-turn prolongsits career in the field. It has a material hardness of C15 to C16 on a Rockwellscale compared to 3004.H22 irrigation tube, whichtested at C10 to C12. which improved this product’swear rate by 41% over conventional aluminumvacuum tubing and a tensile strength of 35 KSI, whichmakes the Tuff Tube 28% more dent resistant overconventional vacuum tubing available and providesbetter ovality. For more product options, please see our Parts List Sheet.

Link: Welded Male Bandlock ® Style / Hydro Cuff End (S8500-00455AHE)

-

Aluminum Weld-on Serrated Crown (UA34767)

For more product options, please see our Parts List Sheet.

-

Hydro -Excavation Cuff (USLV6X8)

Replacement neoprene for ASPC Hydro-Excavation tubes. Made in the USA. For more product options, please see our Parts List Sheet.

-

Circular Operator Tube Style Handle (U63404)

Used on all 6” and 8” Tubes for Vactor®, Vac-Con®, Super Products®, Guzzler ® and Aquatech ® Tubes for easier handling. Operator weld-on tube handle and adjustable swivel handle versions available. For more product options, please see our Parts List Sheet.

-

Zip Tube Aquatech® Style Connection (ZIP-A-6”)

Zip Tube® is an all-new hydro excavation suction/water erosion nozzle. It is arugged, quality-engineered tool that can withstand the harsh environment thatcomes with task at-hand.Zip Tube is constructed of .100 wall, 6” or 8” Tuff Tube™ with an external stainlesssteel water ring containing ten (6”) or twelve (8”) stainless steel replaceable jetsthat pulverize soil with water pressure. The soil is then removed by vacuum suctionthrough the tube. Zip Tube is available with a Vactor® style 6” or 8” flange, Bandlock®, or Aquatech® connection options.Features include an adjustable handle with a rubber bump stop tube inside thewater ring. The bump stop protrudes forward to help safeguard the water ring jetsagainst abrasion from rocks, debris and underground services. There is also a rubbersafety tube that is attached to the exterior of the water ring that helps control thespray of water and eroded material that can splatter during the hydro excavationprocess. PRODUCT SPECIFICATIONSWeight: 39 lbs (6”) 45 lbs. (8”)Length: 71”Water connection: 1” F.P.T. swivelHandle adjustment: 39” HeightReplaceable Jets: 10 (6”) or 12 (8”)Tube dimension: 6” or 8” Tuff Tube w/.100 wallConnection options: 6” or 8” Vactor flange6” or 8” female Bandlock6” or 8” female Aquatech For more product options, please see our Parts List Sheet.

-

Zip Tube® Flange Connection (ZIP-F)

Zip Tube® is an all-new hydro excavation suction/water erosion nozzle. It is arugged, quality-engineered tool that can withstand the harsh environment thatcomes with task at-hand.Zip Tube® is constructed of .100 wall, 6” or 8” Tuff Tube® with an external stainlesssteel water ring containing ten (6”) or twelve (8”) stainless steel replaceable jetsthat pulverize soil with water pressure. The soil is then removed by vacuum suctionthrough the tube. Zip Tube® is available with a Vactor® style 6” or 8” flange, Bandlock®, or Aquatech® connection options.Features include an adjustable handle with a rubber bump stop tube inside thewater ring. The bump stop protrudes forward to help safeguard the water ring jetsagainst abrasion from rocks, debris and underground services. There is also a rubbersafety tube that is attached to the exterior of the water ring that helps control thespray of water and eroded material that can splatter during the hydro excavationprocess.PRODUCT SPECIFICATIONSWeight: 39 lbs (6”) 45 lbs. (8”)Length: 71”Water connection: 1” F.P.T. swivelHandle adjustment: 39” HeightReplaceable Jets: 10 (6”) or 12 (8”)Tube dimension: 6” or 8” Tuff Tube w/.100 wall Connection options: 6” or 8” Vactor® flange6” or 8” female Bandlock®6” or 8” female Aquatech® For more product options, please see our Parts List Sheet.

-

Zip Tube Bandlock Connection (ZIP-SP-6”)

Zip Tube® is an all-new hydro excavation suction/water erosion nozzle. It is arugged, quality-engineered tool that can withstand the harsh environment thatcomes with task at-hand.Zip Tube is constructed of .100 wall, 6” or 8” Tuff Tube™ with an external stainlesssteel water ring containing ten (6”) or twelve (8”) stainless steel replaceable jetsthat pulverize soil with water pressure. The soil is then removed by vacuum suctionthrough the tube. Zip Tube is available with a Vactor® style 6” or 8” flange, Bandlock®, or Aquatech® connection options.Features include an adjustable handle with a rubber bump stop tube inside thewater ring. The bump stop protrudes forward to help safeguard the water ring jetsagainst abrasion from rocks, debris and underground services. There is also a rubbersafety tube that is attached to the exterior of the water ring that helps control thespray of water and eroded material that can splatter during the hydro excavationprocess.PRODUCT SPECIFICATIONSWeight: 39 lbs (6”) 45 lbs. (8”)Length: 71”Water connection: 1” F.P.T. swivelHandle adjustment: 39” HeightReplaceable Jets: 10 (6”) or 12 (8”)Tube dimension: 6” or 8” Tuff Tube w/.100 wallConnection options: 6” or 8” Vactor flange6” or 8” female Bandlock6” or 8” female Aquatech For more product options, please see our Parts List Sheet.

-

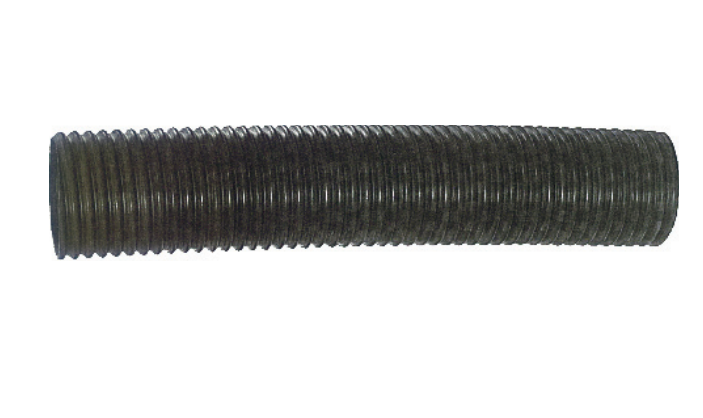

Zip Replacement jet (U40797L)

Zip Tube® is an all-new hydro excavation suction/water erosion nozzle. It is arugged, quality-engineered tool that can withstand the harsh environment thatcomes with task at-hand.Zip Tube is constructed of .100 wall, 6” or 8” Tuff Tube™ with an external stainlesssteel water ring containing ten (6”) or twelve (8”) stainless steel replaceable jetsthat pulverize soil with water pressure. The soil is then removed by vacuum suctionthrough the tube. Zip Tube is available with a Vactor® style 6” or 8” flange, Bandlock®, or Aquatech® connection options.Features include an adjustable handle with a rubber bump stop tube inside thewater ring. The bump stop protrudes forward to help safeguard the water ring jetsagainst abrasion from rocks, debris and underground services. There is also a rubbersafety tube that is attached to the exterior of the water ring that helps control thespray of water and eroded material that can splatter during the hydro excavationprocess.PRODUCT SPECIFICATIONSWeight: 39 lbs (6”) 45 lbs. (8”)Length: 71”Water connection: 1” F.P.T. swivelHandle adjustment: 39” HeightReplaceable Jets: 10 (6”) or 12 (8”)Tube dimension: 6” or 8” Tuff Tube w/.100 wallConnection options: 6” or 8” Vactor flange6” or 8” female Bandlock6” or 8” female Aquatech For more product options, please see our Parts List Sheet.

-

12” Aluminum Intake Tube (VE908-12)

All-aluminum tube, used for suction of debris on Vac-All® type machines. Utilizes riveted steel flanges on both ends. Made in the USA. For more product options, please see our Parts List Sheet.

-

12” Aluminum Catch Basin Tube (dig tube) (VE920-20)

All-aluminum tube, used for cleaning debris boxes on Vac-All® type machines. Utilizes a riveted steel flange on one end and a crown end on the other. Made in the USA. For more product options, please see our Parts List Sheet.

-

12"Intake Clamp (VE2557-12)

Steel constructi on, for both 12” steel and 12” aluminum tubing equipped with 13” steel flanges. Used on Vac-All® type machines. Made in the USA. For more product options, please see our Parts List Sheet.

-

8” Steel Intake Tube (U53186)

All-steel tube with welded steel flanges on both ends. Used for suction of debris on Vactor® style machines Made in the USA. For more product options, please see our Parts List Sheet.

-

8” Steel Catch Basin Tube (dig tube) (US54101X)

All-steel tube with welded steel flange on one end and a steel crown end on the other end. Used for cleaning debris boxes on Vactor® style machines. Made in the USA. For more product options, please see our Parts List Sheet.

-

8” Steel Extension Tube (U54101C)

All-steel tube with welded steel flanges featured on each end. Used for tube extension on Vactor® style machines Made in the USA. For more product options, please see our Parts List Sheet.

-

12” Steel Intake Tube (VE808-12)

All-steel tube with welded steel flanges on both ends. Used for suction of debris on Vac-All® style machines. Made in the USA. For more product options, please see our Parts List Sheet.

-

12” Steel Catch Basin Tube (dig tube) (VE820-36)

All-steel tube with welded steel flange on one end and a steel crown on the other end. Used for cleaning debris boxes on Vac-All® style machines. Made in the USA. For more product options, please see our Parts List Sheet.

-

Aquatech® Style Female Steel End w/ Gasket (AT171230A)

Aquatech® style female tube end with gasket. Female AT171230A / AT171240A example shown above w/ sleeve. For more product options, please see our Parts List Sheet.

Link: Aquatech® Style Female Steel End w/ Gasket (AT171230A)

-

Aquatech® Style Male Steel End w/Ring (AT171280A)

Aquatech® style male tube end with riveted sleeve. Supplied with steel ring. The AT171280A, AT171290A AT171290 are shown above without their steel rings. For more product options, please see our Parts List Sheet.

-

Aquatech® Style Steel Ring (AT171180)

Aquatech® steel ring to be used with male tube end. For more product options, please see our Parts List Sheet.

-

Aquatech® Style Reducer with Gasket/Ring (AT238213)

Aquatech® style reducers. The AT238213 shown above. Rings and gasket included, depending on configuration. For more product options, please see our Parts List Sheet.

-

Aquatech® Style Female O-Ring (AT190770)

Aquatech® Style female coupling o-ring. For more product options, please see our Parts List Sheet.

-

Aquatech® Style Male Hose End (AT171160-HS)

Aquatech® style male hose coupler. Includes the steel ring. For more product options, please see our Parts List Sheet.

-

Aquatech® Style Female Hose End (AT171130-HS)

Aquatech® style female hose end. Includes the Aquatech® style o-ring. For more product options, please see our Parts List Sheet.

-

Aluminum Female Coupler (S3000-00784-4)

Female Band-Lok style coupler with gasket. Used on Super Products style vacuum tubes For more product options, please see our Parts List Sheet.

-

Aluminum Male Coupler (S3000-00783-4)

Male Band-Lok style coupler. Used on Super Products style vacuum tubes. For more product options, please see our Parts List Sheet.

-

Bandlock Style Female Coupler Gasket - (Squareback) (S3500-00003A)

Bandlock style gasket, which is placed on the inside of an aluminum female coupler for aluminum tubing. (Squareback) For more product options, please see our Parts List Sheet.

Link: Bandlock Style Female Coupler Gasket - (Squareback) (S3500-00003A)

-

Bandlock Style Female Coupler Gasket - (Roundback) (S3500-00003S)

Bandlock style gasket, which is placed on the inside of a steel female coupler for steel tubing. (Roundback) For more product options, please see our Parts List Sheet.

Link: Bandlock Style Female Coupler Gasket - (Roundback) (S3500-00003S)

-

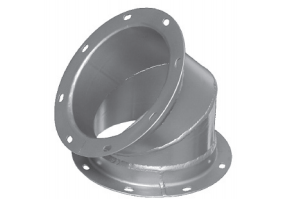

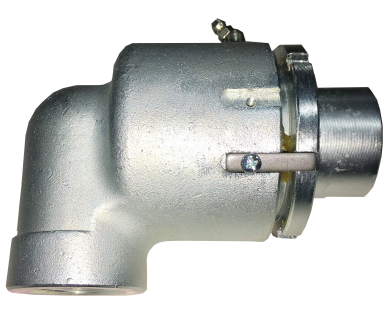

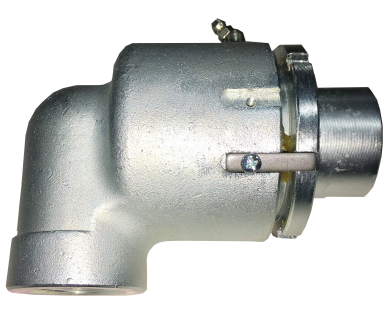

70˚ Boom Elbow (U27771)

For more product options, please see our Parts List Sheet.

Link: 70˚ Boom Elbow (U27771)

-

20˚ Boom Elbow - Steel / Aluminum (U27771AD20S)

Adapter for 70* Boom Elbow to make 90*. For more product options, please see our Parts List Sheet.

-

Steel Female B-Lok Hose End (U42580A)

Female Band-Lok style hose end with gasket. For more product options, please see our Parts List Sheet.

-

Steel Male B-Lok Hose End (U42583B)

Male Band-Lok style hose end. For more product options, please see our Parts List Sheet.

-

Steel Galvanized Bandlock - 90˚ Bandlock (U53492)

90° Bandlock For more product options, please see our Parts List Sheet.

-

Steel Galvanized Bandlock - 45˚ Bandlock (U53494)

45° Bandlock For more product options, please see our Parts List Sheet.

-

Bandlock to Bandlock Reducers / Increasers (S3000-00929T)

Available in both steel and aluminum. Aluminum versions S3000-00929T S3000-00929L and steel version S3000-00929C are shown above. Please check the part number and descriptions for both options. For more product options, please see our Parts List Sheet.

Link: Bandlock to Bandlock Reducers / Increasers (S3000-00929T)

-

Pipe Flanges (U20735)

Steel in construction, these circular flanges are used on Vactor® or Vac-Con® tubing applications. Made in the USA. For more product options, please see our Parts List Sheet.

Link: Pipe Flanges (U20735)

-

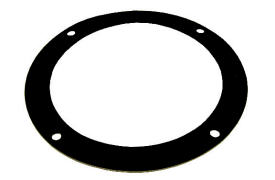

Rubber Flange Gasket (U16585-1)

Vactor® and Vac-Con® style rubber flange gasket. For more product options, please see our Parts List Sheet.

-

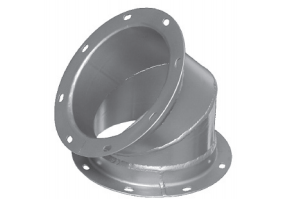

EZ Flange (U40011D)

Aluminum EZ Flange is a weld-on flange used on Vactor® and Vac-Con® tubing For more product options, please see our Parts List Sheet.

Link: EZ Flange (U40011D)

-

8” Flange to 6” Tube Reducer Fitting (U40011C)

This specially-designed aluminum fitting clamps to an 8” flange and welds to a 6” aluminum tube on the opposite end. Maintains airflow efficiency by design. For more product options, please see our Parts List Sheet.

-

Flanged Steel Weldment (U53348)

Vactor® and Vac-Con® style hose end weldment. Steel construction. Widely known as a top hat. The U53348, U58795 U58795H are pictured above. For more product options, please see our Parts List Sheet.

-

Reducer Plate (U34615)

Vactor® and Vac-Con® tubing flanged reducing plate with slotted f anges. Steel construction. For more product options, please see our Parts List Sheet.

Link: Reducer Plate (U34615)

-

Transition Reducers (U35096)

Vactor® and Vac-Con® style flanged transition reducer with slotted flanges. U35096, U34614, U36096E and U35096SP pictured. For more product options, please see our Parts List Sheet.

-

45˚ Steel Pipe Flange (U53197)

Vactor® and Vac-Con® 45° steel dual flange For more product options, please see our Parts List Sheet.

-

90˚ Steel Pipe Flange (U52985)

Vactor® and Vac-Con® 90° steel dual flange For more product options, please see our Parts List Sheet.

-

H.A.T. – ASPC Hose Adapter Thingy® (ASPHAT-6”)

AN EFFICIENT WAY TO SECURE 6” ADS 6” KANAFLEX® STYLE (SPIRAL) SUCTION HOSES 8” FLAT FLANGE and B-LOK TO 6” HOSE *Attaches to the truck in seconds.*Works with 6” Kanaflex® Style Hose.*Cures all the headaches from Duct tape! *Safer and more secure connection.*Durable and long lasting material.*Look at all the time you’ll save from using the HAT!*Works with 6” drain tile and suction hoses. *Not to be used on cuffed debris hose.*Requires no tape, no tools.*Prevents outward spray ASPC Patent # 10.024.044 B2 For more product options, please see our Parts List Sheet.

-

Flange To Bandlock Dust Box Reducers (ASP-6MR)

The ASP-6MR ASP-8MR are pictured above. For more product options, please see our Parts List Sheet.

-

TELESCOPIC FIBERGLASS POLES (ASPDC-EXT)

*Attaches to operator’ Debris Basketwith quick release attachment. *Not a “Hot Stick” – Not for use in energizedlines. *Polymer protective surface veil prevents fiberBlooming at the surface due to abrasion or ultraviolet light. Offers great control and exceptional bending strength with a hollow core. *Tested to 100KV per foot for five minutes. *Wall Thickness .125”, Pole Diameter 1.25”, Weight 2.4lbs.(Based on 6’ Extension Pole).For more product options, please see our Parts List Sheet.

-

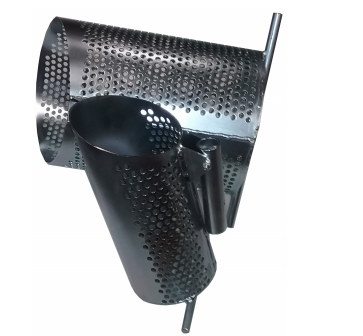

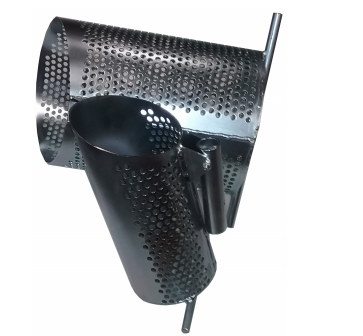

DEBRIS/GRIT CATCHERS (ASPDC-6P)

AN EFFICIENT WAY TO CAPTURE DEBRIS WHILE JETTING *Attaches to operator’ fiberglass Pole with quick release. POLE SOLD SEPARATELY. *Rope attach options ship with 25 foot poly rope (attached). *Durable and long lasting material. *Available in 6” – 18” sizes to suit varying line sizes. *Plated for durability extended life. For more product options, please see our Parts List Sheet.

-

Vactor® Style Cuffed Rubber Debris Hose (U44155)

For more product options, please see our Parts List Sheet.

-

Vactor® Style Cuffed Debris Hose Assembly (U54428)

Assembly ships w/ (2) U58795 Weldments (2) U42594 King Clamps. For more product options, please see our Parts List Sheet.

-

Compression Joints (U45716)

The Compression Joint is used on Vactor® and Aquatech® style equipment. For more product options, please see our Parts List Sheet.

-

King Clamp (U42592)

The King Clamp can be used on all vacuum machines with cuffed rubber debris hose to hold to steel weldments. The best clamp-to-hose contact circle in the industry. For more product options, please see our Parts List Sheet.

Link: King Clamp (U42592)

-

10” Vactor® Style Debris Suction Hose (U47394)

Rubber hose to be used on Vactor® style 2100 machine without cuffs. For more product options, please see our Parts List Sheet.

-

Kanaflex Style 180AR Hose (Cut Lengths) (U43321)

Used on Vactor style machines, Kanaflex is lighter duty than debris hose, but provides more flexibility. For more product options, please see our Parts List Sheet.

-

Heavy Duty Cuffed Debris Hose (U46564A)

For more product options, please see our Parts List Sheet.

-

Extra Heavy Duty Cuffed Debris Hose (U46564B)

For more product options, please see our Parts List Sheet.

-

Kanaflex Style 180AR Hose (w/ Ends) (U52763)

Used on Vactor style machines, Kanaflex style is lighter duty than debris hose, but provides more flexibility. For more product options, please see our Parts List Sheet.

-

Kanaflex Style 180AR Hose (Bulk Length) (U43322-LENGTH)

Used on Vactor style machines, Kanaflex style hose is lighter duty than debris hose, but provides more flexibility. For more product options, please see our Parts List Sheet.

Link: Kanaflex Style 180AR Hose (Bulk Length) (U43322-LENGTH)

-

Power Clamp (U43784)

The Power Clamp is used to hold Kanaflex Style hose onto steel hose ends. (Right Hand Winding) For more product options, please see our Parts List Sheet.

Link: Power Clamp (U43784)

-

Aquatech® Style Cuffed Rubber Debris Hose (AT176620)

Heavy duty style debris hose used on Aquatech® style machines. For more product options, please see our Parts List Sheet.

-

Vac-All® Style Cuffed Rubber Debris Hose (V02390-0165B)

Heavy duty and light duty style collection/debris hose used on Vac-All® style machines.For more product options, please see our Parts List Sheet.

Link: Vac-All® Style Cuffed Rubber Debris Hose (V02390-0165B)

-

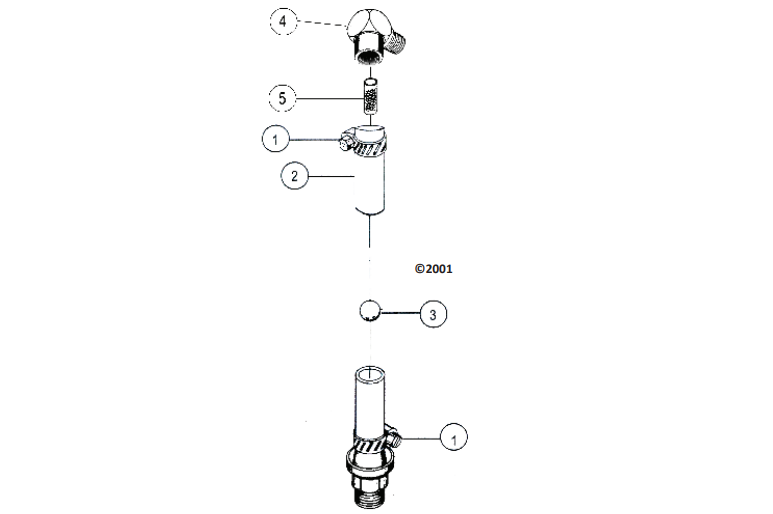

Vac-All® Style Swivel Ball Joint Assembly (V680-0001)

The Vac-All® style swivel ball joint assembly is used to allow free rotation of intake debris hose on Vac-All® style machines. 12” in diameter, and manufactured to O.E.M. specifications. Constructed of chrome-plated steel. For more product options, please see our Parts List Sheet.

-

Elgin Style Cuffed Rubber Debris Hose (ES1011454)

Heavy duty style debris hose used on Elgin style machines. For more product options, please see our Parts List Sheet.

-

Clean Earth® Style Cuffed Rubber Debris Hose (CE32030029)

Heavy duty style debris hose used on Clean Earth® style machines.For more product options, please see our Parts List Sheet.

Link: Clean Earth® Style Cuffed Rubber Debris Hose (CE32030029)

-

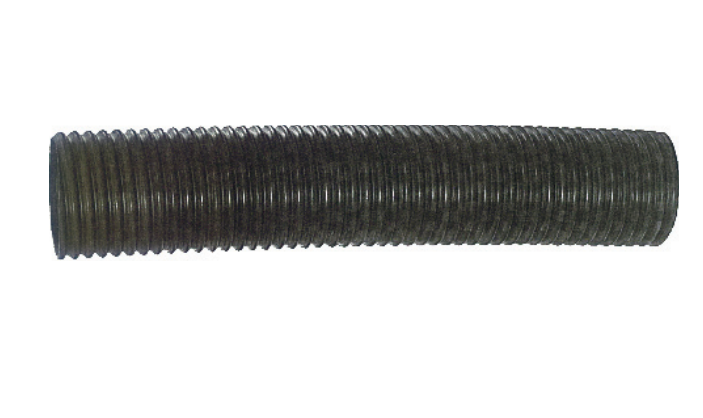

TUFF TUBE® Leader Hose (ASPHH/4X10)

The Toughest Hose Down the Line For more product options, please see our Parts List Sheet.

-

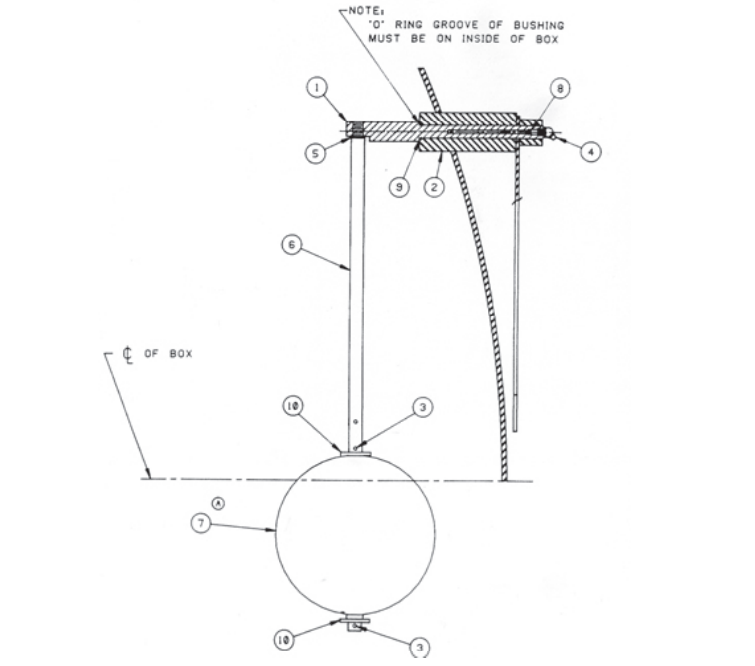

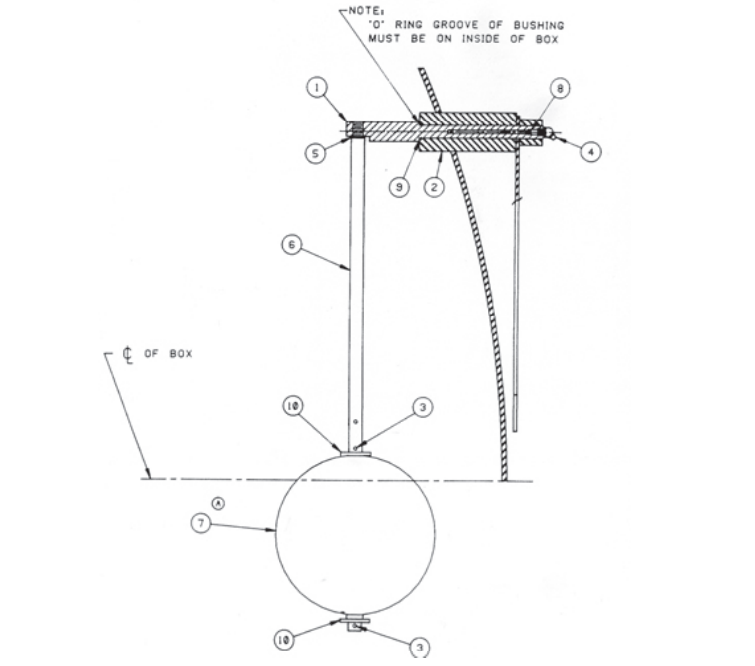

Float Indicator Assembly Parts (U37130)

(Assembly Required) For more product options, please see our Parts List Sheet.

-

6” Stainless Steel Float Ball (S7300-01935)

6” stainless steel float ball used on Super Products® type machines as vacuum breaker in a vacuum debris tank. Made in the USA. For more product options, please see our Parts List Sheet.

-

6” Stainless Steel Float Ball w/ ½” Bore (U45113)

6” stainless steel float ball with 1/2” bore tube to connect onto a slide rod to monitor debris tank capacity used in the debris tank in Vactor®, Guzzler® and Vac-Con® type machines. Made in the USA. For more product options, please see our Parts List Sheet.

-

8” Stainless Steel Float Ball (S3000-01395)

8” stainless steel float ball used on Super Products® type machines as a vacuum breaker in the debris tank. Made in the USA For more product options, please see our Parts List Sheet.

-

9” Stainless Steel Float Ball (S3000-01406)

9” stainless steel float ball used on Super Products® and Guzzler® type machines as a vacuum breaker in the debris tank. Made in the USA For more product options, please see our Parts List Sheet.

-

10” Stainless Steel Float Ball (U44388)

10” stainless steel float ball used on Vactor® and Vac-Con® type machines as a vacuum breaker in the debris tank. Made in the USA For more product options, please see our Parts List Sheet.

-

12” Stainless Steel Float Ball (U44388A)

12” stainless steel float ball used on Super Products® and Guzzler® type machines as a vacuum breaker in the debris tank. Made in the USA For more product options, please see our Parts List Sheet.

-

14” Stainless Steel Float Ball (U44478)

14” stainless steel float ball used on Vactor® and Vac-Con® type machines as a vacuum breaker in the debris tank. Made in the USA For more product options, please see our Parts List Sheet.

-

26" Water Tank Fill Gauge Assembly (U55742)

Used on Vactor® and other sewer cleaners to monitor the water availability in the water tanks. 26" For Models 2100, 810, 800, 815, 1200 Custom tube lengths not available For more product options, please see our Parts List Sheet.

-

45" Water Tank Fill Gauge Assembly (U58101)

Used on Vactor® and other sewer cleaners to monitor the water availability in the water tanks. 45" For Models 400, 810E Custom tube lengths not available For more product options, please see our Parts List Sheet.

-

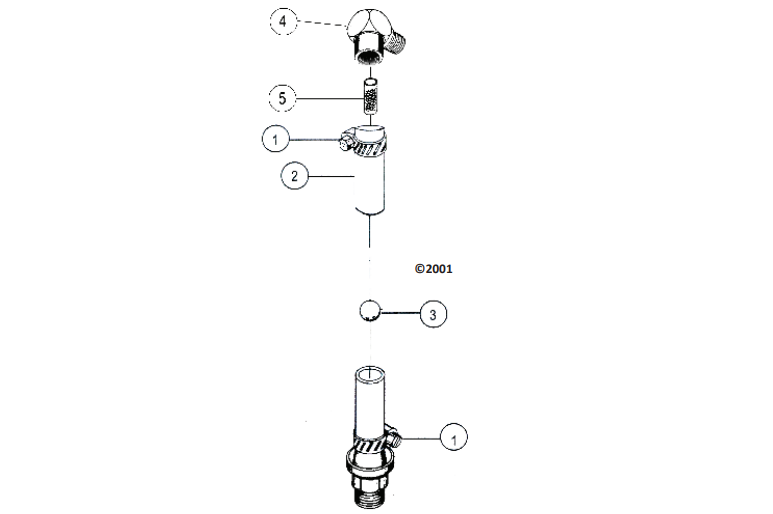

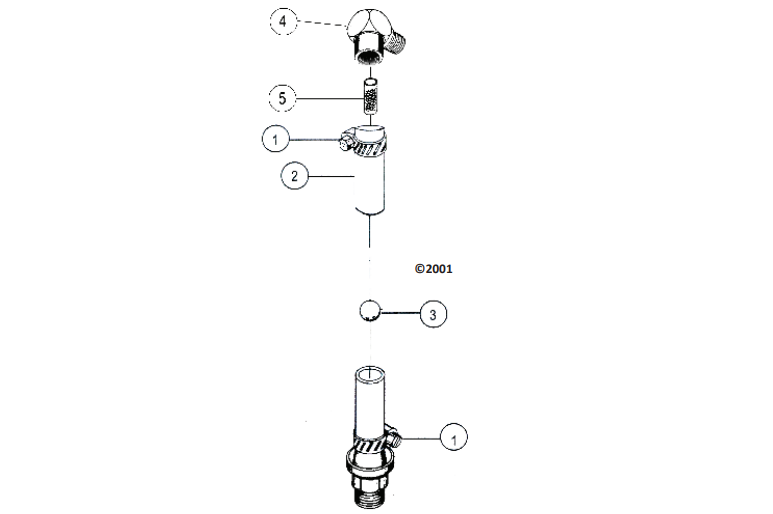

26” Water Tank Fill Gauge Assembly Parts (U55742 Parts)

Used on Vactor® and other sewer cleaners to monitor the water availability in the water tanks. 26" For Models 2100, 810, 800, 815, 1200 Custom tube lengths not available For more product options, please see our Parts List Sheet.

Link: 26” Water Tank Fill Gauge Assembly Parts (U55742 Parts)

-

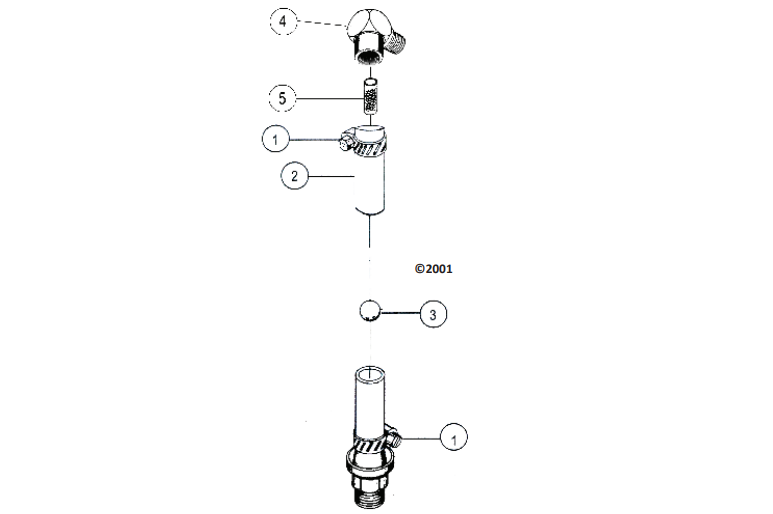

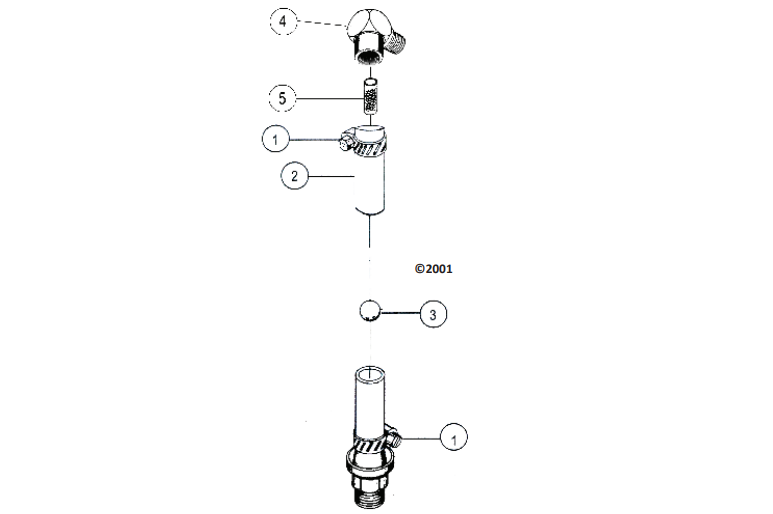

45” Water Tank Fill Gauge Assembly Parts (U58101-Parts)

Used on Vactor® and other sewer cleaners to monitor the water availability in the water tanks. 45" For Models 400, 810E Custom tube lengths not available For more product options, please see our Parts List Sheet.

Link: 45” Water Tank Fill Gauge Assembly Parts (U58101-Parts)

-

RAM Swivel - 90° (U40052A)

RAM swivel joints are manufactured and engineered to exacting specifications. Only the highest quality materials are used in manufacturing this product to ensure the purchaser a quality, dependable swivel with a longer life and less down time than competitive models. Advantages of the RAM Swivel The Housings are a steel investment cast for a longer life. The Gland Nuts are Heat Treated for a longer wear. The Rotary Sleeve is Heat Treated for longer wear and milled with (2) fl at areas that are machined on the rotary sleeve for wrench-ti ghtening. The Backup Ring is Nickel plated to prevent rust Zerk Fitti ngs are installed to lubricate for longer wear. All parts are interchangeable with TM® manufactured swivels. MADE IN THE USA. For more product options, please see our Parts List Sheet.

-

Supreme Saw Blade – Flat (Carbide) (7600F-6C)

2” x .156” tempered spring steel 44-47 HRC 18" - 24" Carbide tipped flat blades are spoke reinforced For more product options, please see our Parts List Sheet.

-

Mainline Root Cutter Kits (950-0000C)

It has been said fewer options are the key to getting a job done. Mainline Root Cutter Kits were not born out of that theory. Starting with a standard Mainline motor, you can pick the type of skids; standard, wheeled or donut and then choose the type of saw blade that you would like for your application; flat, concave or spiral to fit your needs. The power source that drives the heavy-duty mainline root cutter system is a 5.9 c.i. high-torque, low RPM hydraulic motor. It is designed for sewer cleaning machines from 35 to 80 GPM at 900 to 2000 PSI. Its tail nozzle is available in 1” FPT. Made in the USA. For more product options, please see our Parts List Sheet.

-

Tyger Tail Hose – Standard Lengths (D0-69)

Tyger Tail® hoses are used to protect sewer cleaning hose and to guide hose through rough manholes and pipe edges of the transitioning pipe. Tyger Tail® hoses are offered in standard 2" x 36" and 3" x 36" lengths and include a 24' poly rope with a looped end for easy grip. This rope is attached to the Tyger Tail® hose clamp to make installation and removal from manholes easier. Tyger Tail® hoses stay flexible in sub-zero temperatures and tolerate high temperatures as well. Many uses for the Tyger Tail® hose include - Liquid or material suction from machine to machine Liquid transfer from truck to depot Liquid transfer from vat to tank Construction and excavation Protection for sewer cleaning hose Protection for televising tv cable For more product options, please see our Parts List Sheet.

-

ASPC Hose Swage Machine - Hydraulic (UEM110-ASPC)

Adaptability, ease of use and end-user savings; they are three of the founding principles of what has followed since its humble beginnings back in 1989.When developed the UEM110-ASPC 12-ton hydraulic hose mending machine, designed for sizes ¾”, 1” and 1 ¼” sewer cleaning hose, it addressed a growing need in the sewer cleaning industry.There have been other mending machines in the market which have been capable of swaging male and female ends as well as hose menders onto sewer cleaning hose. However, none of these brands had the endorsement of all three of the major hose manufacturers on the market; Parker Hanni? n Corp®, Piranha Hose Products® and Eaton Aeroquip®. The ASPC die sets and pushers are universally capable of swaging Parker Hanni? n Corp®, Piranha Hose Products® and Eaton Aeroquip® sewer jetting hose. Sewer Cleaning “Thermoplastic” Hose is identi?ed by the following: -Yellow inner tube is manufactured by Piranha® Hose Products. -Grey or Red inner tube is manufactured by Parker Hannifin Company.-Blue inner tube is manufactured by Eaton Aeroquip® Hose Company.-Purple inner tube is manufacturered by Schieffer Co. International.-Cream inner tube is manufacturered by Unisource® (Poly-Flow).-Orange inner tube is manufacturered by DYNA FLEX Inc.All sewer hose and repair fitting tools are manufacturered to the National Solid Waste Management Association (formaly WEMI) standards. To protect against PERSONAL INJURY OR DEATH, inspect and repair sewer hose per NSWMA standards.When using sewer cleaning hose and mending equipment, the swage and crimp equipment, including dies and fittings, MUST be of the same manufacturer. ASPC disclaims any responsibility for any hose assembly not produced in conformance with the above specifications. Made in the USA.**WARNING**FAILURE TO COMPLY MAY RESULT IN HOSE BURST OR COUPLING BLOWOFF WHICH MAY LEAD TO PROPERTY DAMAGE, SERIOUS INJURY OR DEATH.For use with standard sewer and jetting hose. Not for use with Cobra, Slither or Armor Belt Hose. Made in the USA. *Authorized by Parker Hannifin Corp, Piranha Hose Products and Eaton Aeroquip Gator® Hose. For more product options, please see our Parts List Sheet.

-

Safety Manhole Cover / Roller "Splash Guard" (D0-6MRFSG)

* Attaches to each ASPC safety manhole cover manhole roller* Helps protect the user from exposure to a sewer’ environmental elements* Fits most industry standard grated manhole covers (21.38” O.D.)* Quick release handles for easy, efficient effective application* Made of .236 polycarbonate for lasting durability* Additional “Splash Guard Flap” and other replacement parts sold separately* WARNING: DO NOT STEP or STAND!! (when in manhole roller use) For more product options, please see our Parts List Sheet.

Link: Safety Manhole Cover / Roller "Splash Guard" (D0-6MRFSG)

-

Camlock Catch Basin (Various Sizes/Styles - dig tube) (MCL372CB)

For more product options, please see our Parts List Sheet.

Link: Camlock Catch Basin (Various Sizes/Styles - dig tube) (MCL372CB)

Categories

Sewage & Drain(800)666-0766 (800)-666-0766 +18006660766

Map W137 N5560 Williams Place

Loading map...